UC Berkeley Web Feature

Keasling and Cal: A perfect fit

BERKELEY – For Jay Keasling, the $42.6 million Gates Foundation grant will bring him closer to realizing a dream — to use his breakthrough technology to produce a cure for malaria that's inexpensive enough to benefit the poor in mosquito-ridden countries around the world.

Graduate student Doug Pitera (left) and Jay Keasling inspect a sweet wormwood plant growing in their lab. They hope to extract from wormwood the genes involved in the synthesis of artemisinin, then insert these genes into laboratory microbes to build bacterial factories for the drug. (Peg Skorpinski photo) |

"I'm particularly attracted to research for developing world problems," said Keasling, UC Berkeley professor of chemical engineering and bioengineering. "There is so much research funding focused on diseases of the Developed World and so little funding for diseases that impact the rest of the world, particularly the poor. Because of the lack of funding, very few researchers are working on these diseases, there is not much competition, and if you find the solutions, you can really make a difference."

Keasling recently made headlines when he traveled to Samoa to sign a landmark agreement between UC Berkeley and the Samoan people to return to them half of any profits from production of a promising anti-AIDS drug he hopes to produce using similar breakthrough technology.

Now, thanks to the Gates grant, he will seek to create in his laboratory an inexpensive antimalarial drug, artemisinin, that he says could be sold for one-tenth of today's price. That's 21 cents, about the price of chloroquine, the former front-line antimalarial that now is meeting resistant strains of the disease around the world.

"The Gates Foundation is performing a very unique role in supplying the development costs for this drug so we can offer it to the people in the developing world at cost," he said. "Our goal is to make the most effective drug available today — artemisinin — as inexpensive as the drugs that are no longer effective."

The Gates grant for a malaria cure was awarded to a unique, three-way partnership through one of the partners, the Institute for OneWorld Health. The other partners are UC Berkeley's California Institute for Quantitative Biomedical Research (QB3), of which Keasling is a faculty affiliate, and Amyris Biotechnologies.

A pioneer in synthetic biology

Raised on his family's corn, soybean and cattle farm outside Lincoln, Keasling attended nearby University of Nebraska. There, he developed an early interest in microbiology that he went on to pursue through a Ph.D. in chemical engineering from the University of Michigan and a one-year postdoctoral stint at Stanford University.

By the time he arrived at UC Berkeley's Department of Chemical Engineering in 1992, he had a hybrid background of chemical engineering and biochemistry and novel ideas about how to re-engineer enzyme reactions in microbes.

At the time, chemical engineering was moving beyond the petrochemical industry into biotechnology, where bacteria were being adapted as chemical factories. Keasling was at the forefront of an area now dubbed "synthetic biology."

"Chemical engineers are good at integrating lots of pieces together to make a large scale chemical plant, and that is what we're doing in modern biological engineering -- we're taking lots of little genetic pieces and putting them together to make a whole system," Keasling said. "Really, we are designing the cell to be a chemical factory. We're building the modern chemical factories of the future," one of which is the technology he hopes will one day produce antimalarial drugs.

Last year at Lawrence Berkeley National Laboratory, he was appointed head of the first synthetic biology department in the country, and he's also working to build a synthetic biology center at UC Berkeley. His lab work already has resulted in engineered bacteria that clean up toxic waste, including heavy metal contamination, and he's trying to create a bug that feeds on nerve agents and organophosphate pesticides.

His bacterial factories to produce artemisinin originally were designed to produce isoprenoids — a broad class of chemicals important to industry — and will be useful not only to create drugs, but also flavors and fragrances. The factories were designed and constructed by two post-doctoral fellows (Vincent Martin and Jack Newman) and two graduate students (Douglas Pitera and Sydnor Withers) in Keasling's laboratory.

To Keasling, however, the advantage of creating chemical factories inside bacteria is not solely a less expensive product, but also a more environmentally-friendly production process. Traditional synthetic chemistry inherently produces toxic waste products — the solvents and reagents typically used in chemical reactions. In addition, extraction from plants risks environmental destruction, especially if it requires the harvesting of rare plants from the wild. A complete chemical factory inside a living cell avoids both these problems.

A mission to help society, the environment

The need for an inexpensive version of artemisinin was brought home to Keasling and the pharmaceutical industry shortly after the World Health Organization and other global donors jointly urged nations to adopt artemisinin-like drug combinations as the preferred treatment for malaria. Not long after that April 2004 announcement, drug companies, which make a combination drug treatment from the wormwood plant, began to hear of Asian speculators who were buying up the plant and hoarding it. According to a recent New York Times article, the price of the plant has quadrupled, driving up the cost of the drug and making it even less accessible to the world's poor, who need it most.

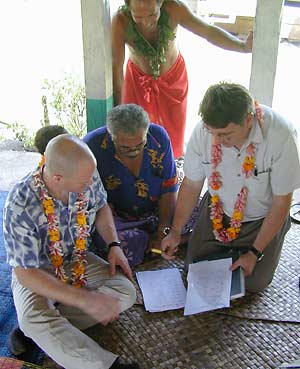

UC Berkeley's Jay Keasling (left) and ethnobotanist Paul Alan Cox (right) sign agreement with village elders in Samoa, agreeing to share with them any royalties from sales of an anti-AIDS drug derived from the native mamala tree. (Photo courtesy Steven King) |

"I'm looking at our timeline, thinking, is there anyway we can speed this up?" said Keasling, referring to what he envisions as a five-year program in his lab to bring his bacteria-derived artemisinin drugs to Food and Drug Administration approval. "Even our timelines, which are extremely aggressive, may not be aggressive enough for what's needed."

As his UC Berkeley lab colleagues, along with Amyris Biotechnologies and the Institute for OneWorld Health, work to make this a reality, Keasling's lab is creating bacterial chemical factories to inexpensively generate a variety of other drugs and with less environmental damage. He plans to make the anticancer drug taxol, a product of the Pacific yew tree, for example, by tweaking the bacterial factory he already has. And he plans to produce Prostratin, the promising anti-AIDS drug first isolated from the native mamala tree in Samoa.

In August, Keasling traveled to Samoa with ethnobotanist Paul Alan Cox to sign an agreement with the Samoan people guaranteeing them a share of any profits from his planned production of the drug. Cox is a renowned biologist and director of the National Tropical Botanical Garden in Hawaii who lived with the Samoans for several years in order to learn from their healers about native remedies and possible plant sources of new medicines.

Once Keasling's lab extracts the genes used by the tree to make Prostratin, it will use them to create a bacterial factory similar to the one now successfully producing chemicals to be turned into artemisinin.

Working at the right place

That UC Berkeley wholeheartedly agreed to make sure the Samoans -- who first found the drug and used it — profit from future production by Keasling of Prostratin makes him proud to be a part of the campus. He said he can't imagine pursuing his research goals anywhere else.

"In my mind, UC Berkeley signing the agreement with the Samoan people was just the right thing to do," he said. "The Samoan people wanted to see this drug get used — it was not just about money, but about establishing their place in the world and development of their intellectual property.

"I think there is a culture here — you see it in the undergraduates and in the graduate students — a culture of trying to do something more than just make a lot of money or get a degree. It's about trying to do something in an area where it will help people."

Pitera, the graduate student, exemplifies that campus culture. With barely a year to go before finishing his Ph.D., he hopes to stay on campus a little longer to see the artemisinin project to fruition.

"When I started, we didn't even think of artemisinin as an end product. I was more interested in whether we could do this in an environmentally friendly way," Pitera said. "Since we have chosen an end product, artemisinin, our research might actually affect people. … It's seldom that you have a chance to really have such an impact with your work, which this project could have. It's a nice driving force."

The work of the Keasling lab also epitomizes the mission of the California Institute for Quantitative Biomedical Research (QB3), of which Keasling is a member. Formed four years ago as a state, private and federally-funded research center involving UC Berkeley, UC San Francisco and UC Santa Cruz, its aim is to apply the tools of the physical sciences and modern biotechnology to outstanding problems in biomedical research.

The artemisinin project "is a great example of QB3 in action," Keasling said. "We're taking a natural product in short supply, using biotechnology to produce it and to produce it very inexpensively in the developing world. It is a real motivation for graduate student and post docs working at the bench with day-to-day details, knowing that their research will be applied to saving millions of lives."